New Performing Arts School in Detroit Poses Logistical Challenges for Suppliers and Pumpers

The Detroit Public Schools Management Team commissioned the help of several contractors to complete a brand new public high school for the fine, performing communication and media arts outside downtown Detroit. The $75 million project was separated into three separate phases to ensure concrete contractors and steel workers remained on schedule.

Lead general contractor L.S. Brinker of the Brinker Group M.B.E., Detroit, in a joint venture with Skanska USA Building, Detroit operation, had to overcome several obstacles to keep the project on schedule. Phase I of the project consisted of construction of an on-campus auditorium. Although completion of the structure’s foundation eliminated precious working space for crews executing Phases II and III, it was necessary to finish that part of the job to allow several months for tedious ironwork within the structure.

“It created a lot more work for us in Phase II management meetings, but it was necessary,” said Gerald Donnelly, L.S. Brinker Safety Director. Personnel at L.S. Brinker, and Skanska, with the help of supplier and pumping contractors, created blueprints to lay out a plan of attack for Phase II, hoping to eliminate problems with traffic control and job site jam-ups.

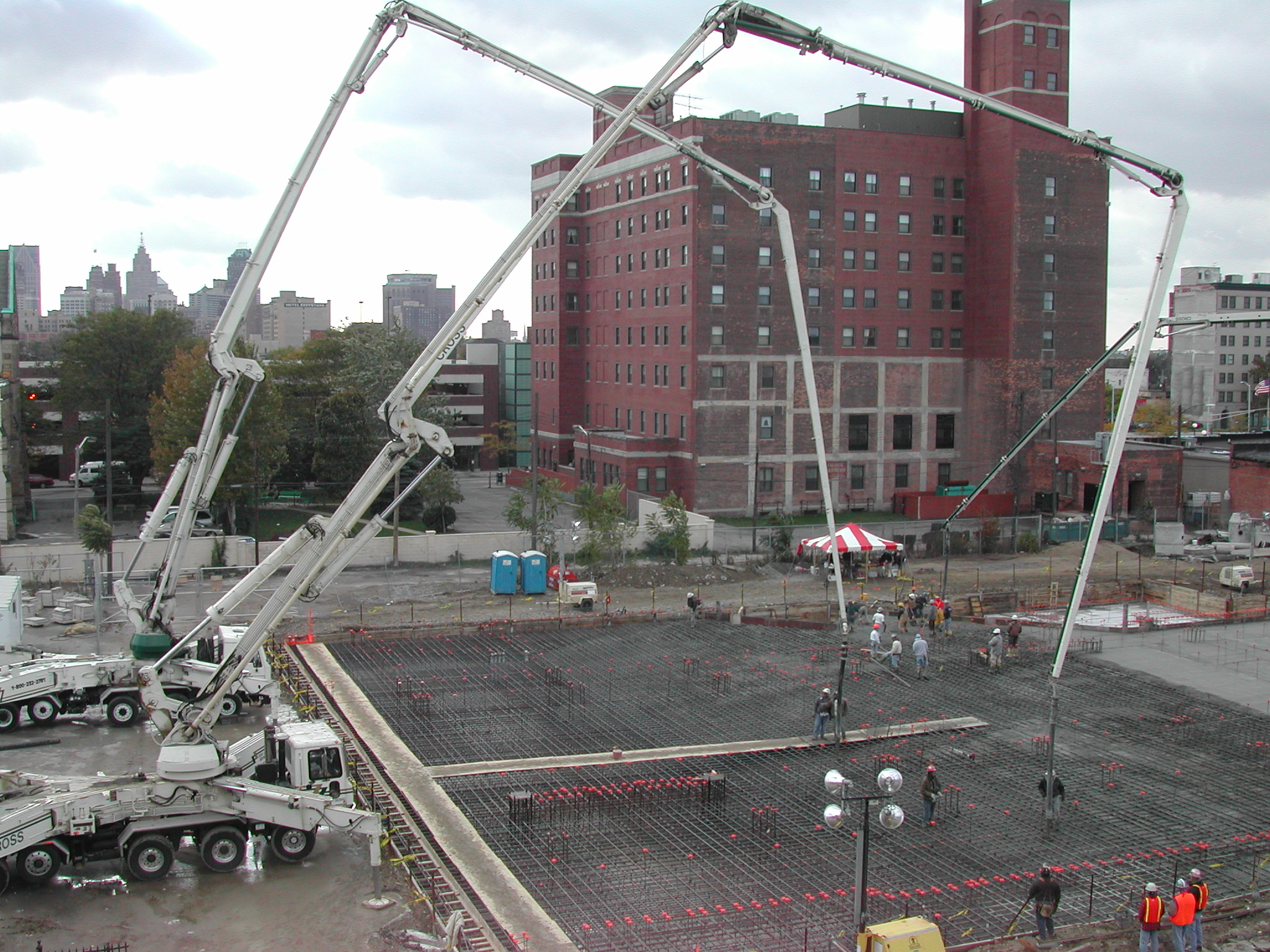

The first part of Phase II consisted of a 100 by 200-foot excavation and foundation pour for one 7-story building, the central area of the new high school. On October 19, 2002, Cross Enterprises, Inc., Melvindale, Mich., used three concrete pumps from their extensive fleet to complete the 2,900-yard mat pour. Two Schwing KVM 55’s and one Schwing S 58 SX were set up at 4:30 am. Both of the 55-meter pumps were positioned next to each other on one side of the square excavation. The 58-meter was set up further from the pour on the opposite side. With the smallest footprint in the industry, the S 58 SX set up in a space as small as 29’-2” by 31’-4”, important on the tight job site. The longest boom available, the S 58 SX’s 187’-10” maximum vertical extension and 175’-2” horizontal reach was able to provide concrete to nearly every corner of the foundation. Schwing recently unveiled the new longest boom, the S 61 SX, with 198 feet of reach. All three carrier mounted concrete pumps with 4-section placing booms remained in their setup positions and worked continuously throughout the 9-hour mat pour.

“We used three of Cross’s pumps because of truck traffic. Two pumps could have completed the pour sufficiently, but with job site conditions as they were, we couldn’t afford to have all of the ready mix trucks grouped around only two pumps,” said Donnelly.

Koening Fuel & Supply, Detroit, in a joint venture with Clawson Concrete Company, Ortonville, Mich. was contracted to supply the concrete. Koenig President Peter Fredericks was involved in pre-pour meetings with Clawson and concrete contractor ELS Construction, Inc., Detroit.

“ELS set production requirements at 400 yards per hour, despite all of the logistical issues,“ said Fredericks, “We set out to meet a goal.”

Armed with 50 ready mix trucks from Koenig and Clawson fleets and with the cooperation of 3 Koenig plants and 1 Clawson plant, suppliers made a valiant effort to keep up with the high production rate of all three Schwing pumps.

Fredericks estimated that ready-mix trucks made around 300 round-trips during the Phase II pour. Contractors were well prepared for heavy traffic on the small site. Maps and blueprints created during pre-pour meetings directed trucks onto the job site via only one entrance, and then routed through the job site to one exit to an adjacent street closed off to public traffic. Ready mix trucks were diverted two blocks from the actual job site to the washout area.

President Charlie Cross said the pumps performed exactly up to par. The Super X Outriggers on the S 58 SX came in handy for quick and compact set-up on the restrictive job site. Schwing’s Generation III technology combined with the manufacturer’s longest stroke pumping cylinders provided maximum output on the pour. Because of heavy truck traffic and crowded conditions, the pumps were provided enough concrete to pump 300 yards per hour, 100 yards per hour shy of the intended production.

Phase III of the project, completed January 2003, was the excavation and 4,000-yard foundation pour for another 7-story building, directly adjacent to the Phase II mat pour.

Donnelly says Cross Enterprises and ready mix providers anticipated problems similar to those in Phase II. “It was 1,000 yards larger than the first, and with another huge portion of the job site gone, we had the same issues to deal with.”

Fredericks had solid confidence in his fleet’s performance. “My main concern was the January weather. Obviously traffic control and tight job site conditions were definite factors once again, but we were up to the challenge.”

Cross Vice President Frank Ferretti utilized the 55 and 58-meter pumps once again for Phase III. Cross Enterprises has seen its fair share of challenges, and their reliable fleet of pumps is always up to the job. A giant mat pour at the Detroit Metro Airport required the use of 12 of Cross’s pumping fleet. The contractor completed the pour in a world record-setting 22 hours. Cross’s fleet achieved a Guiness Book of World Records listing as the force behind the world’s most productive pour.